Michelle Gostic, Sarah Levine, Leah Meyerholtz

Abstract

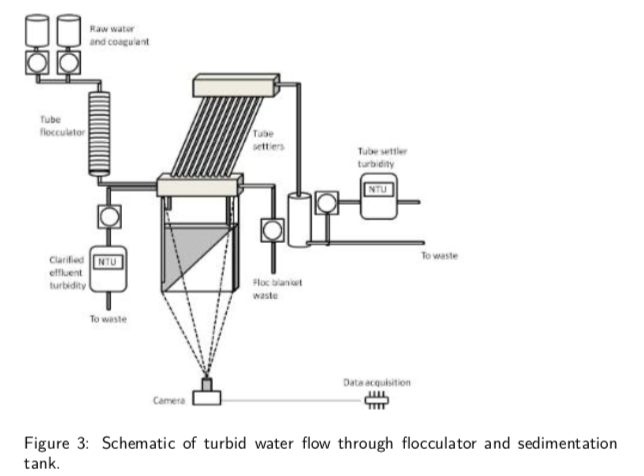

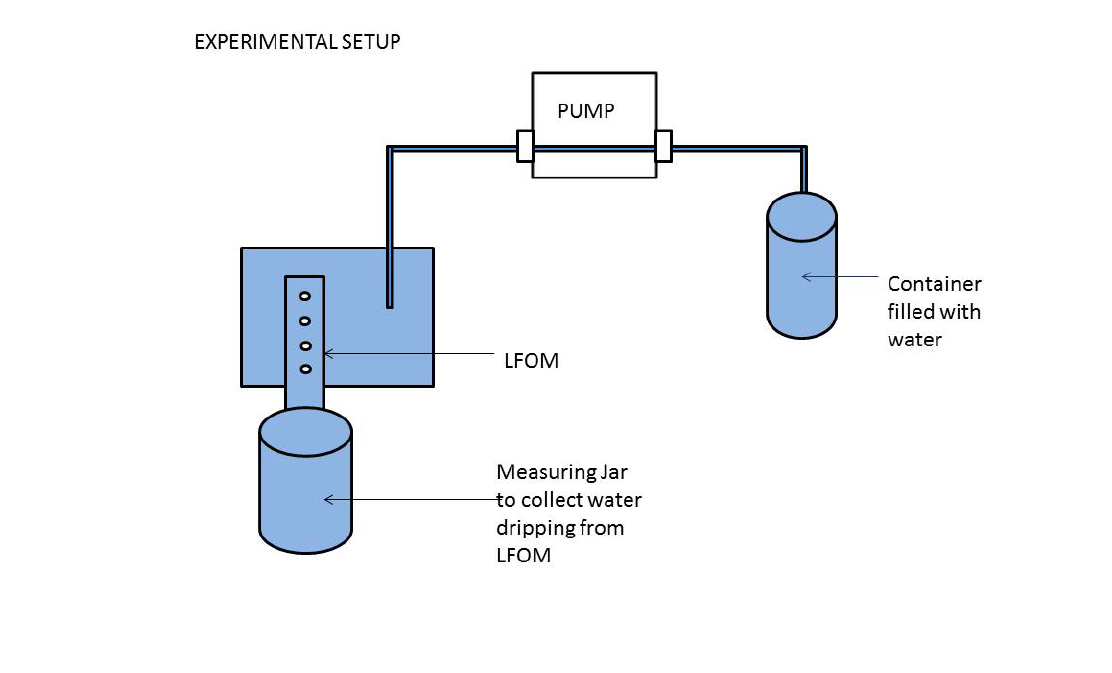

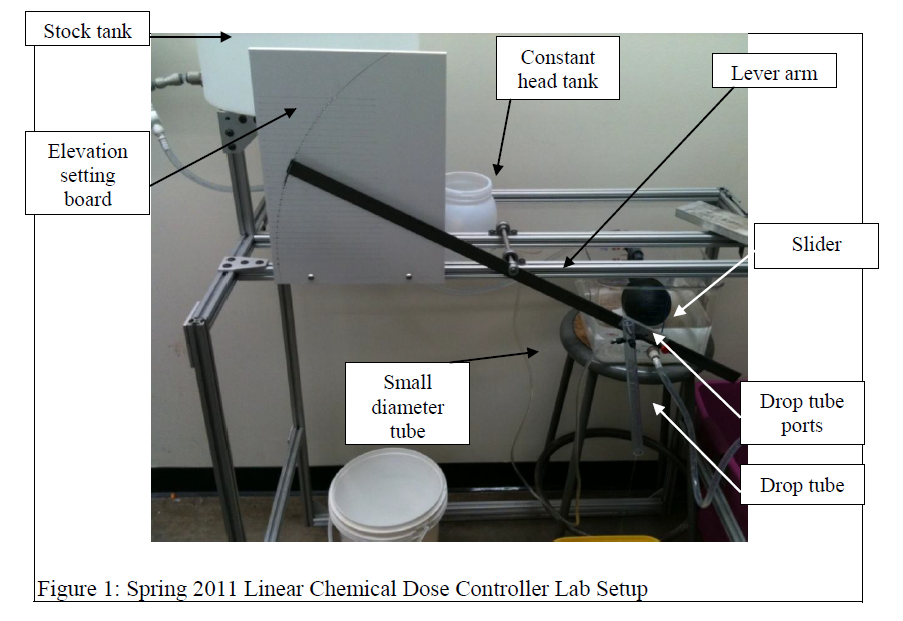

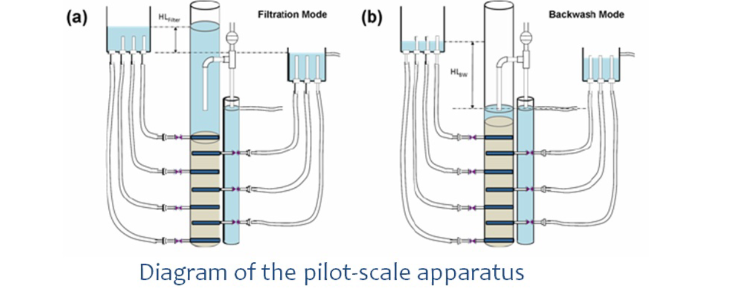

A reticulated polyurethane foam filtration system combined with coagulant dosing has proven capable of providing clean, low-turbidity water; however the necessary addition of coagulant combined with a non-conventional cleaning method makes the foam filtration system inefficient and not ideal to be used on a municipal scale. For this reason, research on foam filtration methods have been geared towards engineering a portable and effective filtration unit to provide clean water to devastated areas in emergency situations. There is a great demand for such technology as proven by the 1994 Rwanda Crisis. In this case, 85-90% of deaths in refugee camps were caused by diarrhea [Toole and Waldman; Doocy and Burnham]. Providing a low-cost, sustainable clean water source in emergency situations is the best way to prevent waterborne diseases and dehydration. The foam filtration team has worked towards designing an apparatus that will provide at least 15 liters of water per day per person, based on the UNHCR’s (United Nations High Commissioner for Refugees) recommendations for refugee situations [UNHCR]. The foam filter is small enough that it can be placed in the back of a pick up truck when needed and hooked up to the car’s engine to harvest electricity needed to power the filtration process. The current AguaClara foam filtration system utilizes a roughing and finishing filter to remove solid particles from influent water. Turbid water enters through the linear flow orifice meter (LFOM), which maintains a linear relationship between the water level and the flow rate of water through the system. Coagulant enters the LFOM in regulated doses to ensure consistent mixing of coagulant with influent water. The water flows through a 30 inch deep roughing filter, consisting of 30 ppi (pores per inch) foam, and then through a 15 inch deep finishing filter, consisting of 90 ppi foam. Before effluent water leaves the system, it is dosed with chlorine and exits the supercritical flow tube. Previous tests showed that head loss from the foam filters was negligible, but recent experimentation with an open system has proven otherwise. Due to the head loss and effluent turbidity standards, the foam filters need to be cleaned. A “plunger” method of cleaning has proven to be an efficient and easy way to clean the foam filters. A long pole with a porous disc attached to one end is used to compress the foam and release solid particles trapped in the 1 filters. This method is similar to squeezing out a dirty kitchen sponge. During the cleaning process, the foam must remain submerged in water to prevent the entrainment of air bubbles that would hinder filter performance. After plunging, the dirty water and released sediment flow out of exit valves located downstream of each filter. At the 2012 National Sustainable Design Expo in Washington D.C. the AguaClara team showed that the foam filter system is effective in removing particles from water at relatively high turbidities; however, data from these tests does not give concrete evidence of the filter’s performance in terms of realistic applications. At the expo, the turbidimeter was not properly calibrated, thus the data collected is not 100% accurate. Additionally, the filters were cleaned every 4 hours. Although this proved that the filters could return to their initial performance level after being cleaned via the plunger method, cleaning every 4 hours may be either too frequent or infrequent to maintain a high volume of treated water with acceptable effluent turbidity, in an emergency situation it is essential to maximize the volume of usable water while still maintaining quality standards. Effluent at the expo was dosed with clay and recycled so that the effluent became the influent. There is a possibility that coagulant built up in the filter columns, due to the recycle, improved performance beyond what it would have been in a more realistic experiment. As a new and relatively unexplored technology, there is much research to be done in the realm of foam filtration. Our current and future research will focus on providing extensive data as to the performance of the foam filtration system at different turbidities as well as identifying more efficient cleaning cycles. The World Health Organization included significantly reducing the number of “people without sustainable access to safe drinking-water and sanitation” in its list of 15 Millennium Development Goals [WHO]. Refining the foam filtration system has the potential to contribute to achieving this goal in addition to providing clean water to those who need it the most.