Danielle Feng, Jill Freeman, Cari Gandy

Abstract:

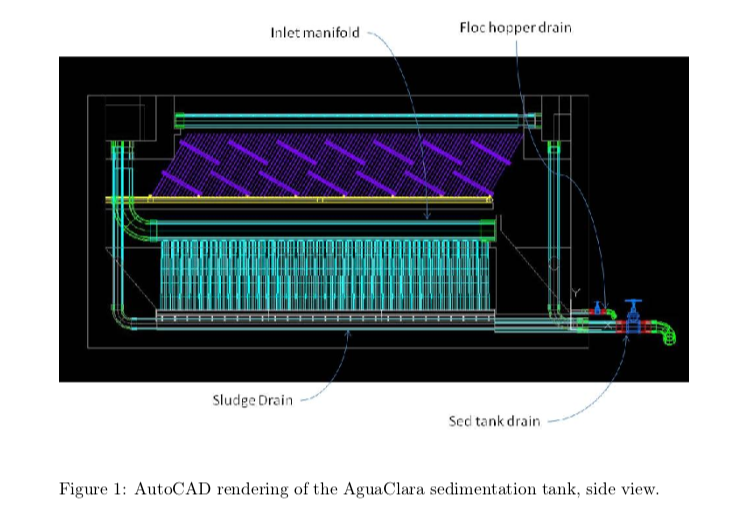

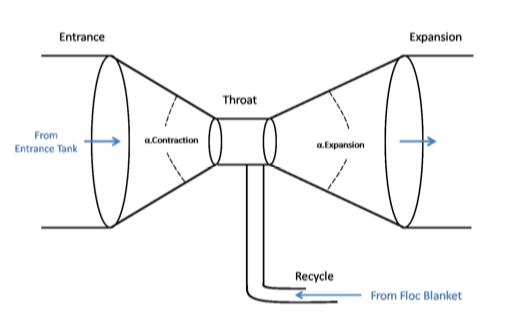

In the sedimentation tank of an AguaClara water treatment plant, water flows through the inlet manifold with vertical diffusers that channel the water into the bottom of the tank as a line source. As water exits the vertical diffusers, a semi circular half pipe jet reverser directs the water upward to resuspend flocs to form a floc blanket, or a dense, fluidized bed of particles, in the sedimentation tank below the plate settlers. A floc blanket increases the particle removal efficiency of the sedimentation tank by capturing smaller flocs that would otherwise escape through lamellar sedimentation. A floc blanket also leads to less clean water waste because without a floc blanket, sludge builds up at the bottom of the tank and will require constant draining. While current plant designs use a 0.5” radius jet reverser and centered jet placement, other jet reverser sizes and jet placements were explored to increase floc resuspension and floc blanket stability. A 1.5” radius reverser with asymmetric jet placement was found to be the optimal design for floc resuspension. Floc blanket stability in relation to coagulent dose was also explored, and optimal alum doses for several influent turbidities were determined.