Po-Hsun Lin

Abstract:

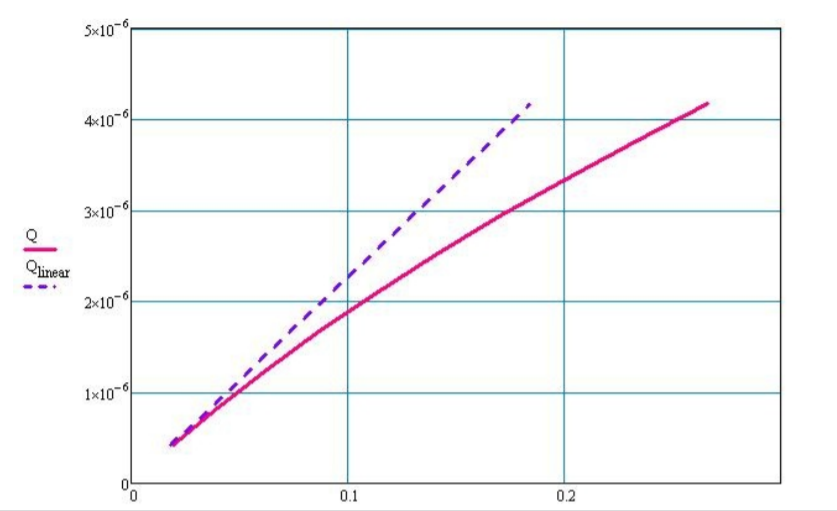

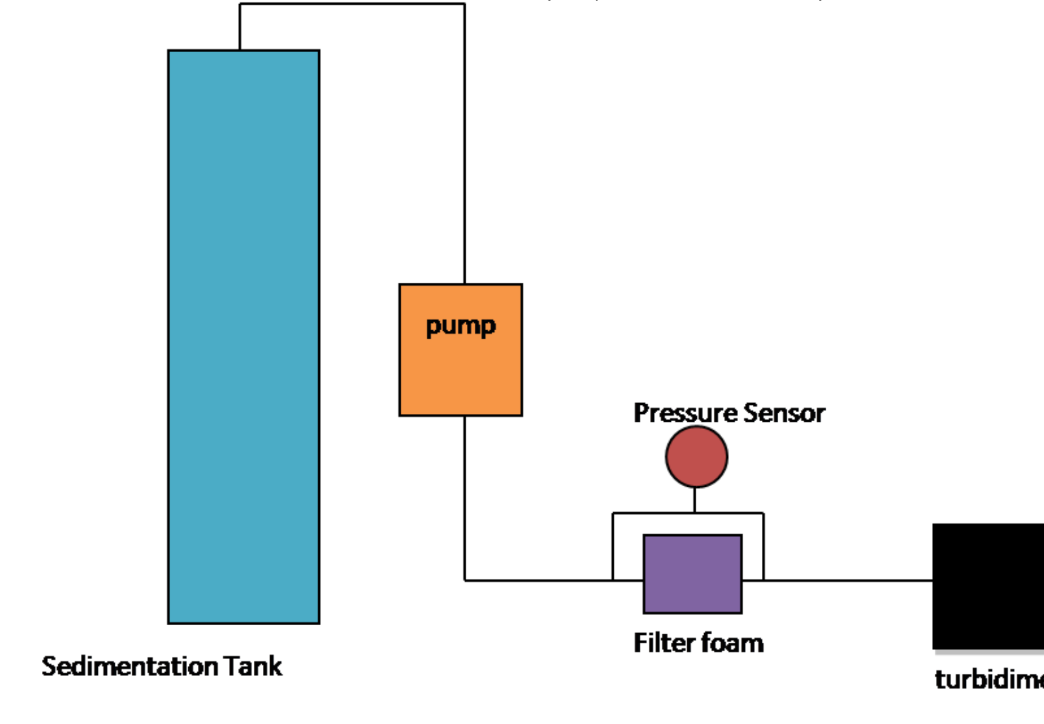

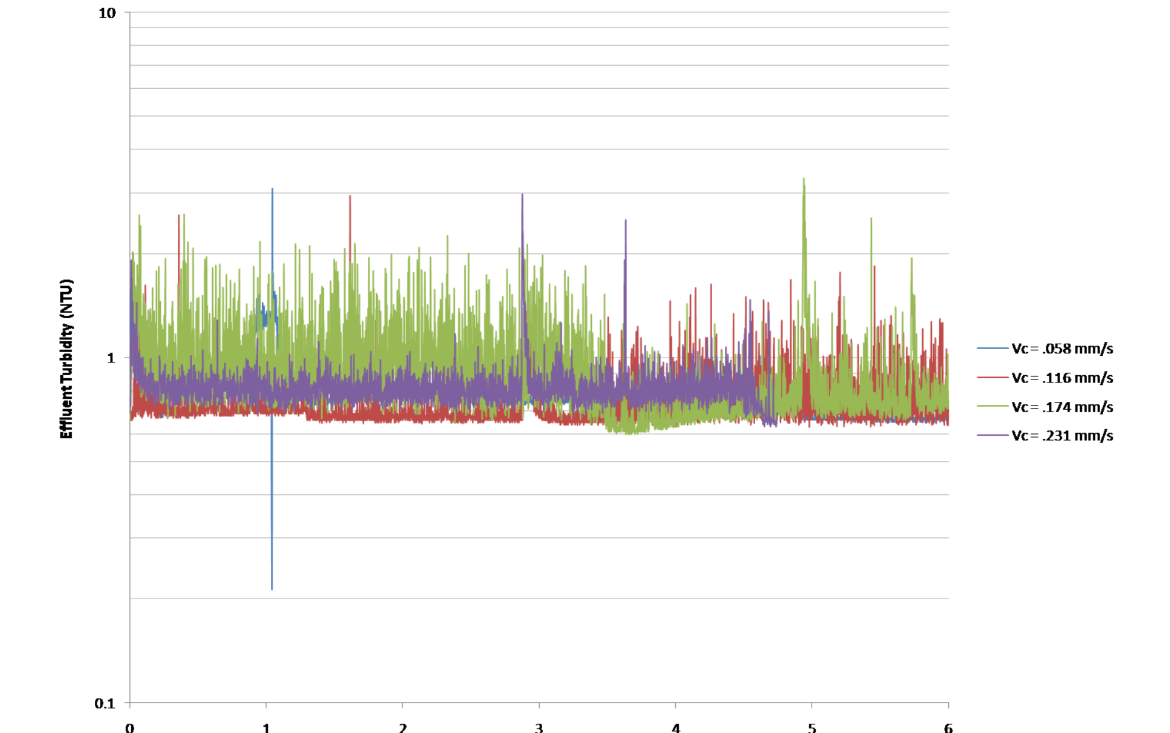

The post sedimentation addition of polyaluminum chloride (PACl) was investigated as a means to enhance particle removal efficiency in rapid sand filtration. The process modification was evaluated in laboratory studies and at the Cornell Water Filtration Plant (CWFP). PACl was continuously metered into CWFP filter influent to increase concentrations by 0.06 to 4.2 mg/L (as aluminum) during the filter-to-waste stage of the filter operation cycle to accelerate filter ripening. Lower influent PACl concentrations ranging from 0.056 to 0.43 mg Al/L were also continuously applied during filtration. In comparison to a control filter that received no PACl addition, the ripening time required decreased with PACl dose, and the incremental improvement in particle removal during filtration increased with PACl dose. The addition of 0.056 mg Al/L of PACl (the lowest concentration tested) significantly reduced initial filter ripening time at the CWFP from 10 hours to 2.5 hours, and effluent turbidity in the test filter over the 77 hour filter run was lower than the control filter by an average of 17%. Incremental head loss increase caused by the PACl feed was dose dependent and was negligible for the lowest dosage tested.