Introduction:

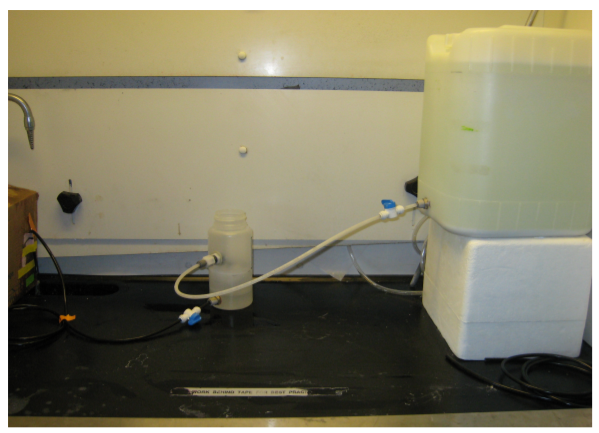

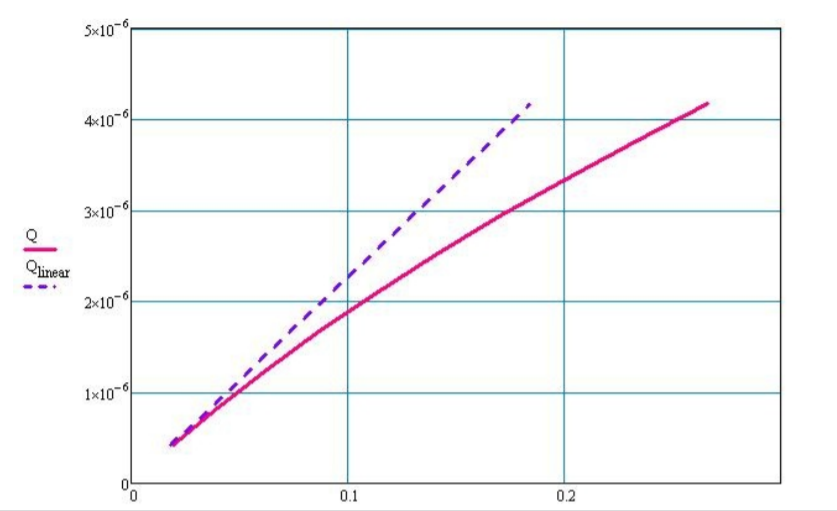

Until recently, the float valves used in the AguaClara's flow controllers were slightly flawed. The float valve connector included a compression nut, which was easily misplaced or misused, leading to leaks. A new float valve would preferably have pipe threads and be able to connect to a quick connect tube fitting. Furthermore, the float on the float valve was replaced in favor of another float, complicating post manufacturing assembly. A new float valve was found with pipe threads, quick connect tube fitting and had a more appropriate valve attached. However, before the new float valve was to be implemented, a study on the attenuation factor (change in pressure from stock tank over the change in pressure in the constant head tank) was to be conducted.