Hyeong Yoon, Thomas Shouler, Joe Beaudette

Abstract:

Our main objective we wished to accomplish this semester was to create a means of automating the design of the columns and walls for the design tool. We began this work by analyzing the structural capabilities of the columns and walls for the Alauca plant.

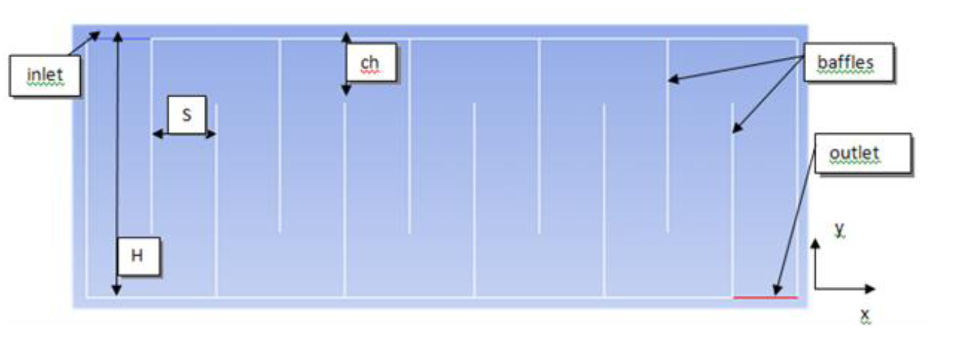

There are three different load cases that guide the design of the columns and walls of the tank. The first case assumed that the tank walls were supported by the surrounding backfill. The second case assumed no support from this backfill. The third case analyzed the structural importance of the rubble which lies at the base of the sedimentation tank.

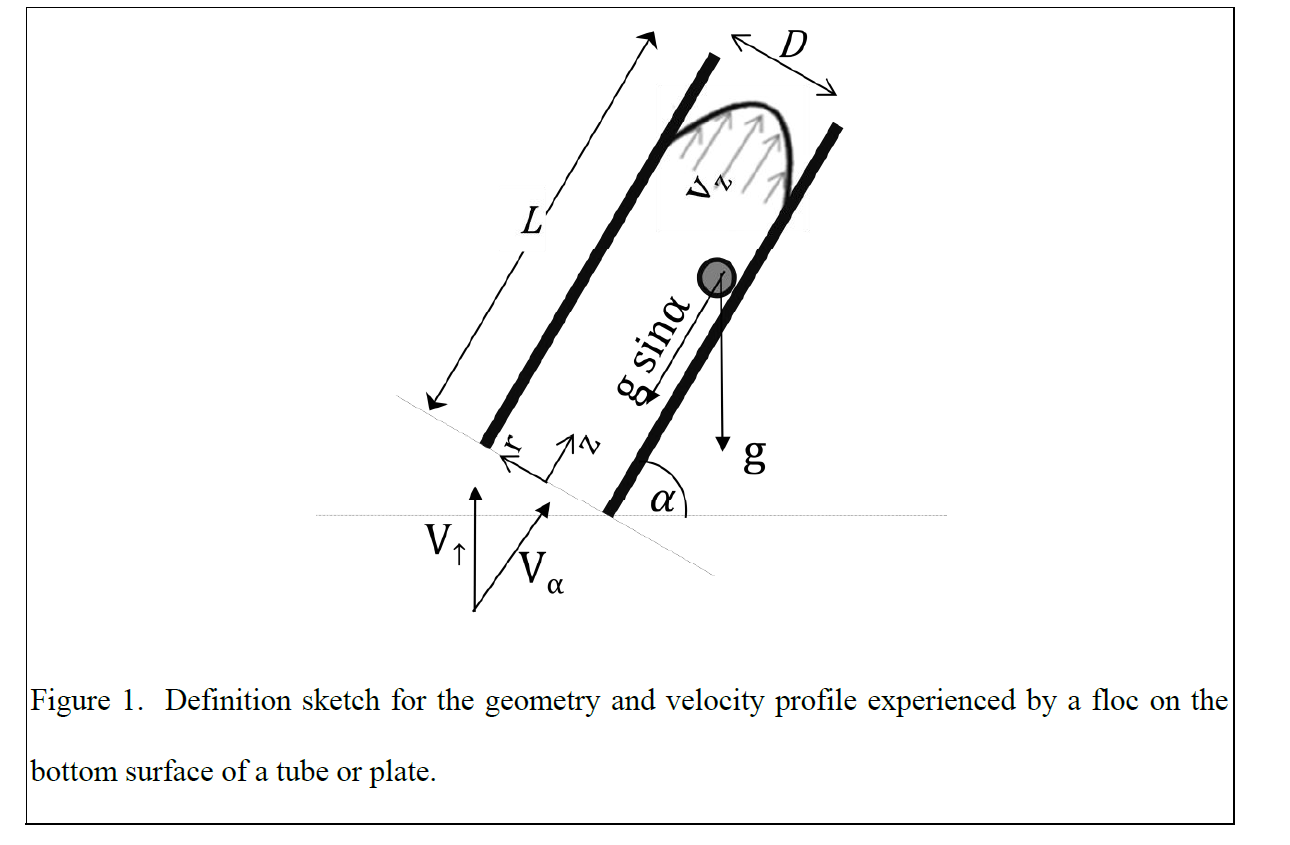

For our analysis of the walls, we modeled them as closely spaced columns. As seen in Figure 1, the vertical rebar that runs through these walls will add flexural support. By modeling the walls as columns we accounted for this vertical rebar. Modeling the walls as a combination of individual columns also allowed us to use the same tools and procedures that we used for the analysis of the columns. We set the moment at initial cracking as our first failure moment. We determined this moment by using the the Transformed Moment of Inertia method. We also wanted to know the moment that would render the walls and columns could experience before ultimate failure. We believed that this value would be of importance for future analyses which would incorporate earthquake conditions. For this ultimate failure analysis, we used the Column Interaction Diagram. This method plots the area of all axial load and moment cases that a column would be able to support safely. All methods are explained in detail in the report.