Validation Studies of Fluent Turbulence Models for Fluent Simulations of AguaClara Flocculators

Travis Stanislaus

Introduction:

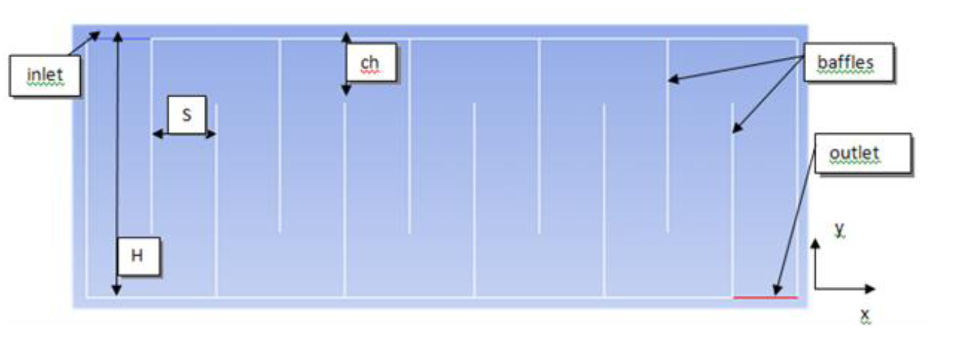

The AguaClara water treatment project uses ANSYS Fluent computational fluid dynamics (CFD) software to simulate and analyze turbulent fluid flow in idealized models of flocculators in AguaClara water treatment plants. The flocculator simulations in Fluent are used to obtain turbulent kinetic energy dissipation rate, ε, and energy loss coefficient, K, between baffle in the flocculator for AguaClara design equations that determine the height of the flocculator, H, the spacing between baffles, S, the quantity of baffles in the flocculator, and flocculation performance, Ѳε^(1/3) , Ѳ is the residence time between two baffles. The results from Fluent are used in the design of AguaClara facilities, so verification and validation of the Fluent flocculator model and simulation has been conducted continuously since the time AguaClara began using Fluent simulations. Verification is determination of the degree the model being simulated is an accurate representation of the developer’s description and solution to the model. Validation is determining if the model is an accurate representation of the real world physics and intended uses of the model.