Dhaval Mehta, Ariel Seidner, Sarah Sinclair, Lishan Zhu

Abstract:

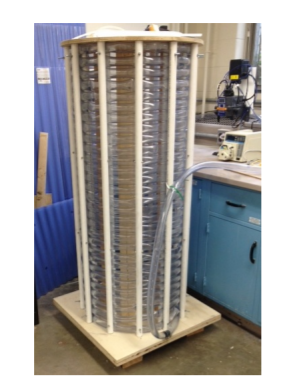

The Low Flow Stacked Rapid Sand Filter (LFSRSF) is a scaled-down version of the AguaClara Stacked Rapid Sand Filter (SRSF). Similar in theory of operation to the SRSF, the LFSRSF is optimized to treat smaller flow rates of 0.8 L/s. The current LFSRSF design in India uses multiple valves to switch from filtration to backwash; the LFSRSF research subteam at Cornell seeks to reduce the number of valves by designing a filter that uses hydraulic controls. In detailing the teams work this semester, this report seeks to accomplish three main goals: to document the design process for such a filter, to document the fabrication process to facilitate easy technology-transfer to India, and to document filter performance as tested to date.

This semester, the team calculated appropriate design specifications for slotted manifold, trunks, plumbing systems and sand for the filter, as well as created a unique flexible-tubing derived sand drain. The team completed all fabrication, and also set up a water-recycle and leak containment system to support testing, as well as a pressure sensor array to test �ow-distribution between sand layers. The team then solved multiple water- and air-leak issues. Ultimately, the team was successful in ensuring that the LFSRSF backwashes easily, efficiently and whenever an operator may so desire.

Teams working on the project further must tackle three major issues: the current �filter cannot handle backwash flow rates greater than around 0.6 L/s, its entrance and exit tanks need to be raised, and the filter also faces significant challenges of larger-than-expected head loss during backwash. Once these issues are solved, the hydraulically-controlled LFSRSF shall be truly ready to be deployed in the field