Felice Chan, Jonathan Christensen, Stephen Jacobs, Ana Oliveira

Abstract

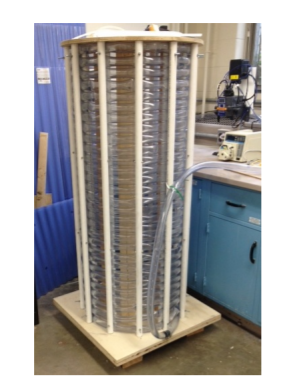

Since the Summer of 2013, the Turbulent Tube Flocculator team has been developing and optimizing a design for a lab scale turbulent tube occulator to better mimic the processes that occur at full scale plants. From this, a vertical occulator of approximately 1.5 m was constructed with 30 coils of exible tubings connected with pieces of metal pipe. Currently, the team is working on the rest of the experimental setup, which involves pumps, turbidimeters, pinch valves, clay stock, temperature and pressure sensors, Settled Water Turbidity analyzer (SWaT), rapid mix, and Process Controller software. Clay will be added directly to the head tank to keep the suspension stable in absence of coagulant. The coagulant, injected immediately following rapid mix, is responsible for aggregation of suspended particles present in the solution. Experiments will measure turbidity reduction as a function of coagulant dosage.