Alexandra Green, Tiago Viegas, Paul Vieselmeyer

Abstract

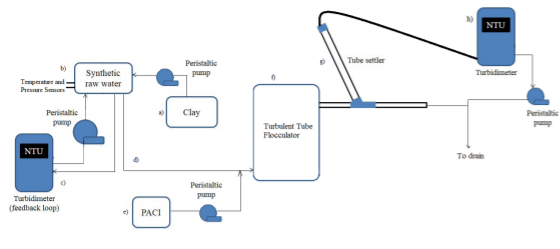

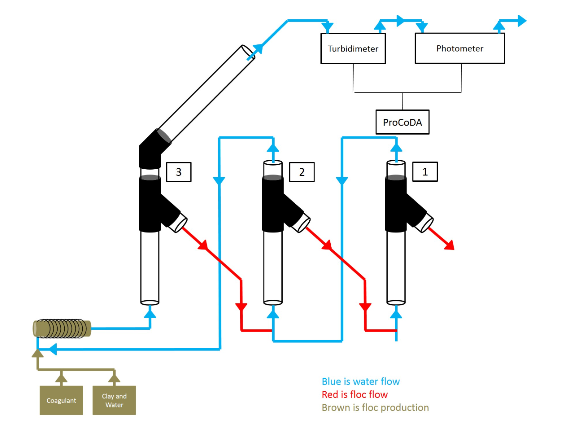

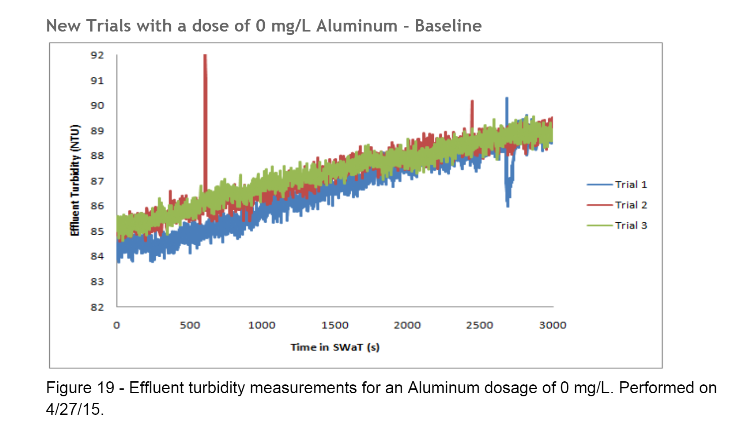

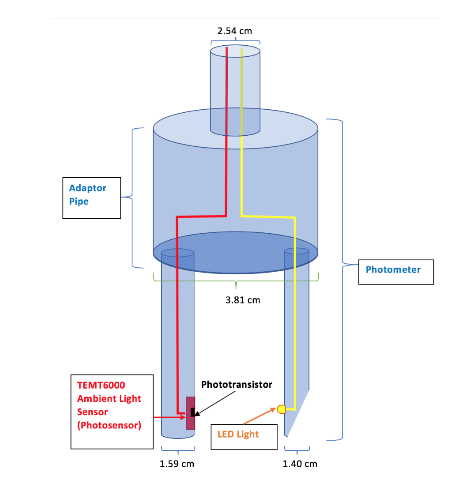

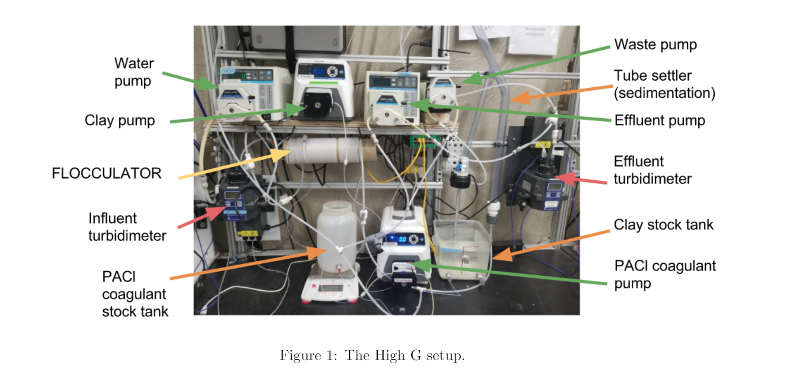

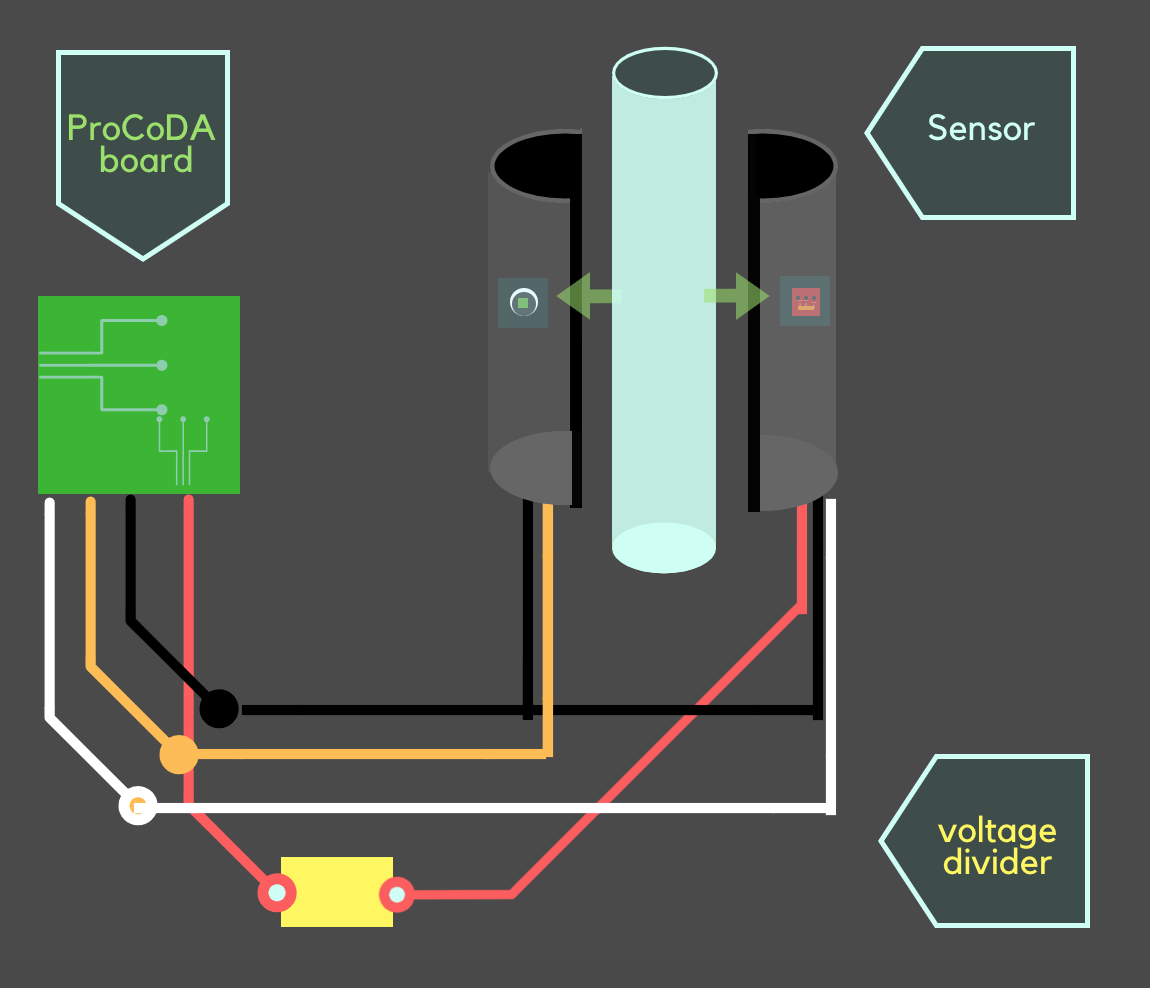

The visualization of the floc blanket in Aguaclara plants has been difficult and limited, so our team has tried to simulate it and create a new apparatus to solve or at least to reduce the problem. We found reports and materials from the turbidimeter team that could help in our task. Research was done on commercial sensors that could help monitor the floc blanket level, but none of the results were feasible. An experimental set up was also created in order to simulate the floc blanket and clear water interface with no success. Finally, a sludge judge apparatus was created to hopefully help with the observation of the floc blanket in San Nicolas.