Marlana Hinkley, Alena Hutchinson, Ethan Keller, Alicia Peters

Abstract:

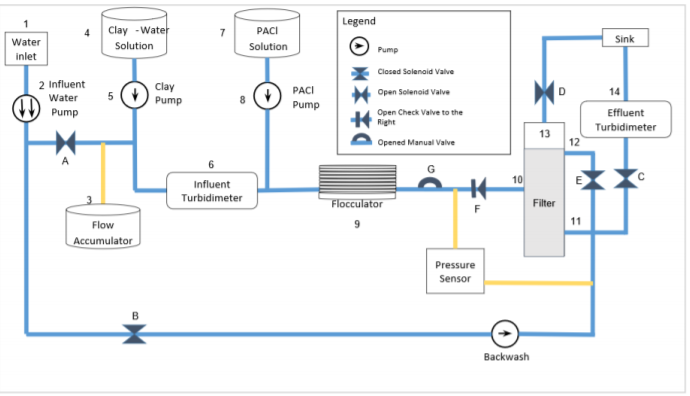

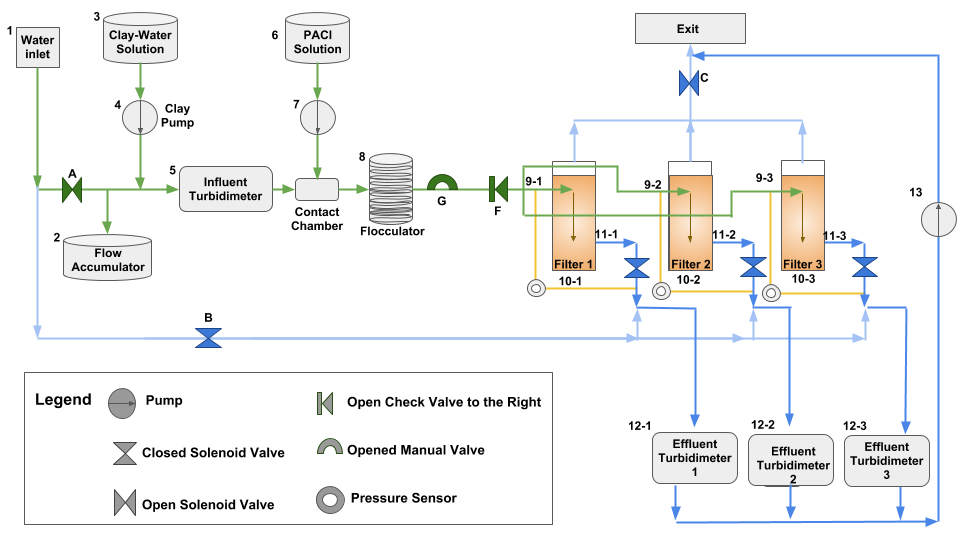

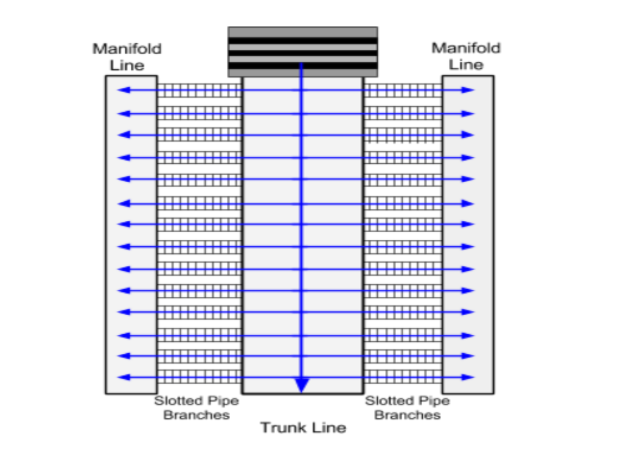

The primary goal of foam filtration is to design a low cost, locally sourced, easy to operate water filtration system. Throughout the semester, backwash cleaning efficiency experiments were performed on the small-scale filter, designed in Fall 2014 to hydraulically model the full scale filter implemented in El Carpintero. The objective of these experiments was to determine an empirical relationship between backwash pore velocity and the percent mass removal of the particles from the foam during the cleaning cycle. Experimentation with different pore sizes revealed a new mechanism for filtration: the foam acts as a sedimentation tank, providing a large surface area for the flocs to settle. This is contrary to the initial hypothesis that coagulant-covered flocs stuck to the inside of the pore walls, and that a large shear force would be required to remove the flocs during backwash. Evidently, there is still much to be understood with regards to the mechanisms behind filtration and backwash.

Apart from work in the laboratory, the team continues to analyze data collected from experiments performed on the full-scale filter in El Carpintero by AguaClara engineer, Walker Grimshaw, to understand the discrepancies between performance in the laboratory and in the field.

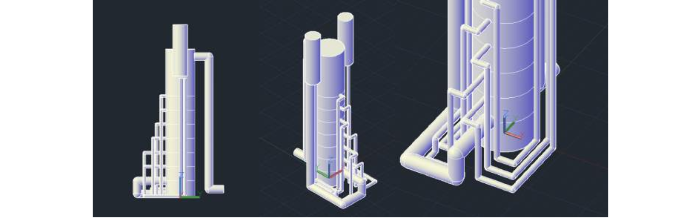

Much of the semester was spent preparing for the EPA P3 Conference held on April 10th and 11th in Washington, DC. The team fabricated a small scale model of the technology, prepared a technical report, and created a poster display for the competition, and received an Honorable Mention for its efforts in creating an “Off-Grid Solution to Drinking Water Treatment.”