Surya Kumar, Larry Ge

Abstract:

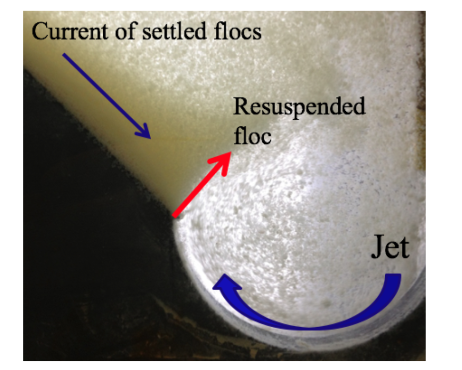

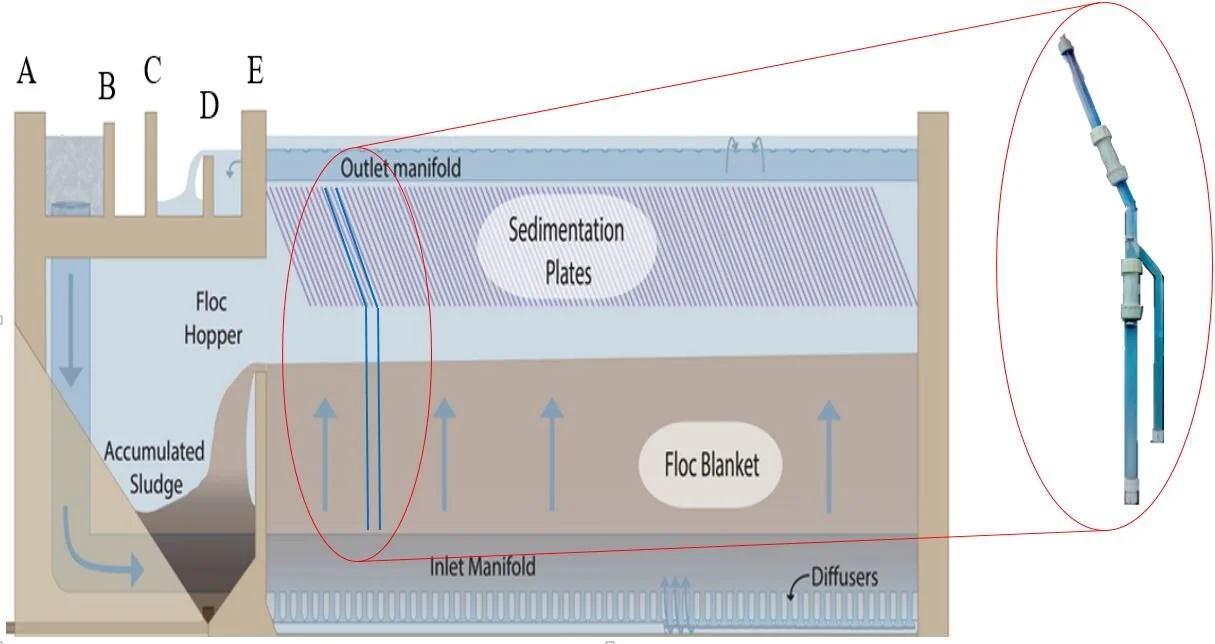

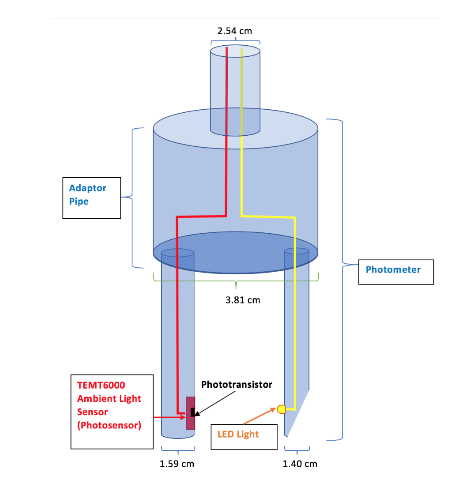

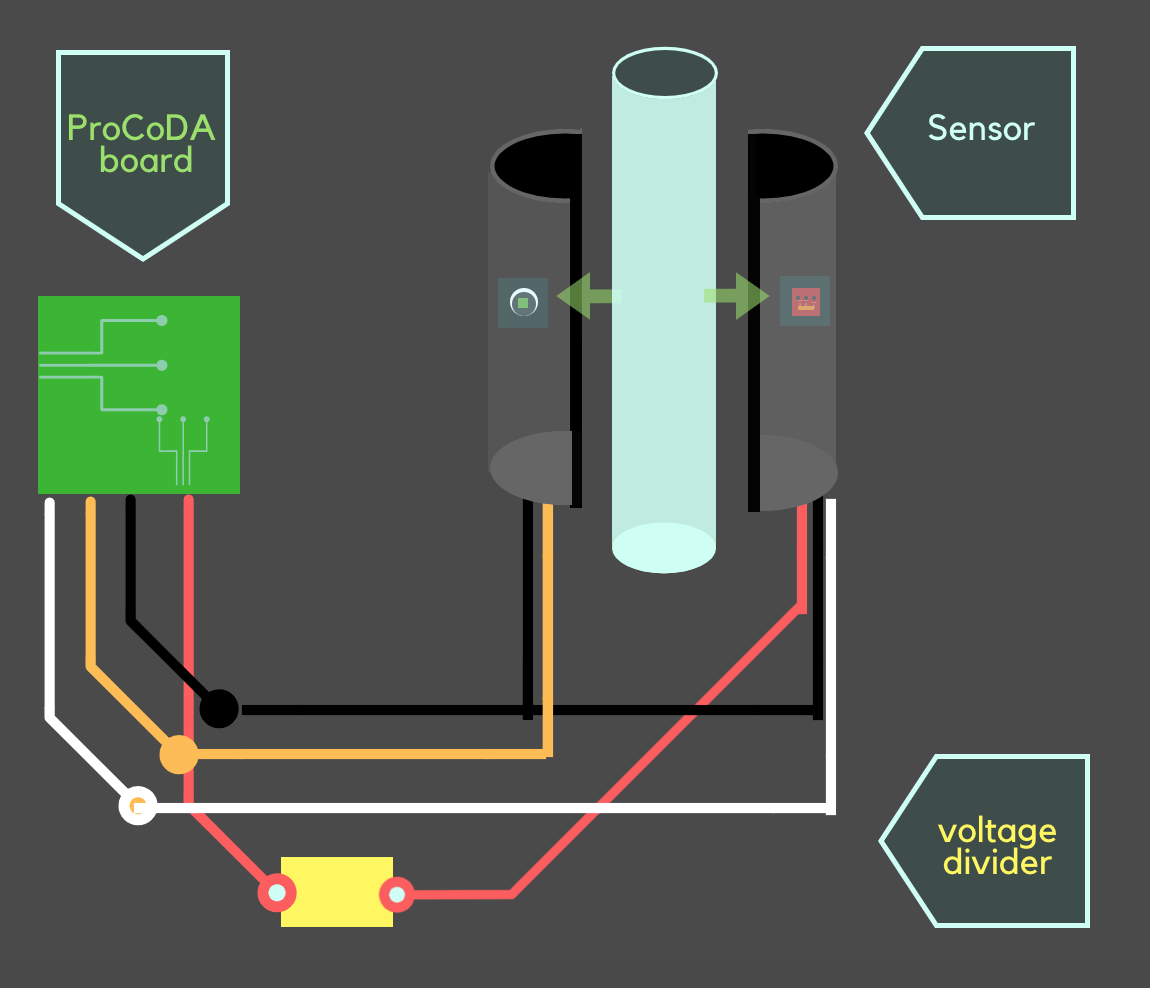

The sedimentation tanks at AguaClara sustainable drinking water treatment plants are performing well, but they can perform better. When floc settles it becomes sludge. If there is sludge buildup in a sedimentation tank, a host of problems follow: uneven water flow through the sedimentation tank, impaired performance, anaerobic digestion, and methane production. However, if a sedimentation tank can be designed to prevent any flocs from settling, then the drinking water treatment process will never have to be stopped, and the sedimentation tanks will never have to be cleaned. AguaClara is investigating the creation/use of a “Floc Probe” to better understand floc behavior and achieve this improved tank design. The research tool will be used to survey currently functioning sedimentation tanks in Honduras to identify where sludge is building up. Sonar has been found to be a potential solution. Sonar can detect substances of varying densities as well as record at what depth the substance was found. This technology can therefore distinguish between flocs and sludge, and can also recognize the amount of sludge buildup.