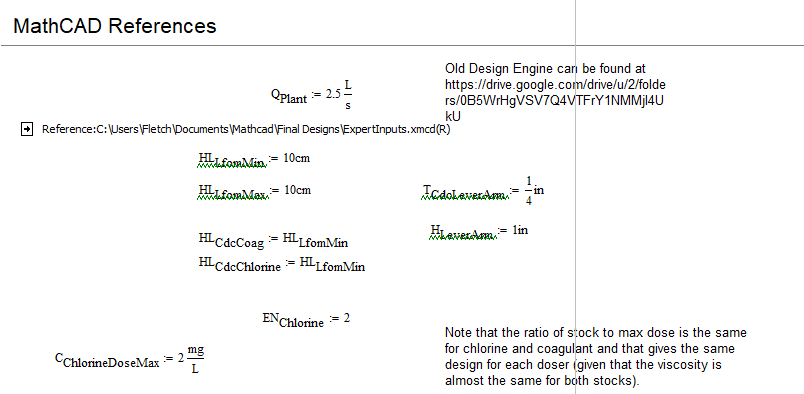

The AguaClara Infrastructure Design Engine (AIDE), our automated water treatment plant design tool, has gone through many iterations since its origins in 2008, when it was based on Mathcad, AutoCAD, Microsoft Word, and LabView. AIDE is now based on Onshape, which has FeatureScript as its built-in programming language that is fully integrated into the CAD environment.

Since our earlier draft of an AguaClara plant, we have been focusing on two major changes. The first was a complete overhaul of the method we use to bring the design algorithms and drawings of subcomponents into higher level assemblies. The second major change was to connect a parts database with our design process so that we could create a bill of materials. A bill of materials is the list of parts required to manufacture a product with their quantities, suppliers, and cost.

An example of a table that shows the output of the bill of materials.

Prices and physical components for each part are taken from part catalogues provided to us by our implementation partners and entered into a database. This database is then integrated into our designs in Onshape, and subsequently each part is automatically assigned a part number upon its entry into the model. This results in the self-generating formation of a bill of materials that includes quantities and prices, as well as a cut list that provides sizes.

The flow of information that results in the bill of materials.

The bill of materials will be incredibly useful in the development of general cost estimates and is especially powerful due to its ability to adapt the price to automatically reflect any changes that are made in the design. With our current plant, it takes under a minute to generate a new design that includes a material cost estimate. We have been meeting with one of our implementation partners, Agua para el Pueblo, to get their feedback on new designs. During this process, we continue to incorporate their suggestions into the design. Below is a quote from an Agua Para el Pueblo engineer, Aminta Núñez Galdámez, describing how the bill of materials affects their work.

Spanish

“... sacar cantidades de obras y hacer fichas unitarias de costos, es un trabajo un poco tedioso, pero se necesita hacer para conocer los costos reales de la planta, y mi meta era poder reducir estos esfuerzos para APP. Esto va a reducir estos tiempos y también será más sencillo estimar costos para diferentes tamaño de plantas, algunas personas interesadas en plantas para su comunidad, juntas de agua o donantes nos consultan cuanto podria costar una planta y nosotros sacamos estimados en base a nuestra experiencia, pero con las actualizaciones de AIDE podemos tener estimados de costos más certeros.”

English

“... creating a bill of materials and unit cost sheets is pretty tedious work, but necessary to obtain the actual cost of the plant, and my goal was to reduce the time needed by APP to obtain this information. The bill of materials (through AIDE) will reduce that time and it will also be easier to estimate costs for different sized plants. People who are interested in plants for their community, community water boards, and donors ask us how much a plant might cost and we create an estimate based on our experience, but with these AIDE updates, we can have cost estimates that are much more accurate.”

Please stay in touch and watch out for further updates on our progress!

Blog Post Author: Izumi Matsuda